25. Apply sealing compound to the oil seal (easy on the sealant… it goes a long way!), and tap it into place using a large socket.

25. Apply sealing compound to the oil seal (easy on the sealant… it goes a long way!), and tap it into place using a large socket.

26. Insert the shaft… the axle shaft… come on now!!

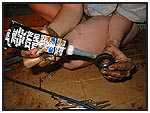

27. Pack the bearings with the red goo, I mean grease, and replace them. Rubber gloves aren’t necessary, but they keep the red goo from getting on everything you touch! There are bearing-packing attachments for grease guns available at your local parts-o-rama, but the idea is to just get grease EVERYWHERE in the bearing. It is truly an art form. 28. Slide the new seals on and reinstall the knuckle — be sure to grease it up good!

27. Pack the bearings with the red goo, I mean grease, and replace them. Rubber gloves aren’t necessary, but they keep the red goo from getting on everything you touch! There are bearing-packing attachments for grease guns available at your local parts-o-rama, but the idea is to just get grease EVERYWHERE in the bearing. It is truly an art form. 28. Slide the new seals on and reinstall the knuckle — be sure to grease it up good!  Now it takes some doing to get the oil seal cover, pad, oil seal, and retainer all sandwiched back together. Just make a game out of it. One bolt at a time. Remember, you control it, it doesn’t control you. Murph had a horrible time trying to figure out how to hold it all together but once he did, it was very easy to imitate. Essentially, put the first seal and metal brackets on the knuckle and bolt them down finger-tight. Then remove two of the bolts and install the left outside bracket, then the right using the same alternating bolt method This is probably the most frustrating part of the project.

Now it takes some doing to get the oil seal cover, pad, oil seal, and retainer all sandwiched back together. Just make a game out of it. One bolt at a time. Remember, you control it, it doesn’t control you. Murph had a horrible time trying to figure out how to hold it all together but once he did, it was very easy to imitate. Essentially, put the first seal and metal brackets on the knuckle and bolt them down finger-tight. Then remove two of the bolts and install the left outside bracket, then the right using the same alternating bolt method This is probably the most frustrating part of the project.

29. Put your kingpins back on applying sealing compound around them….do you remember which was which? You better!

08/11/10 15:12