A case study in tinkering run amok… by TD (Troy) Graham

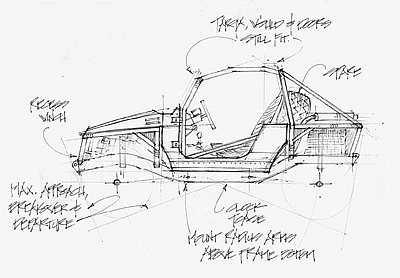

Part 2: Blueprint.

OK, we all remember our folks constantly nagging us to set goals, and as we get older we realize that they are getting smarter by the day. Funny thing, that. So following Mother Dearest’s advice, I applied a little goal-setting to my eternal project:

Linkage Suspension: A whole slew of objectives here:

– 25+ degrees of twist from horizontal in front, 35+ in back (or 2 to 3X the Missing Link flex)- Optimum side-to-side axle “shift” when articulating- Optimum pinion angle throughout entire suspension range- Proper torque reaction design dictating control-arm-to-axle mounting points- Tight on-road handling, minimizing squat, brake dive, and suspension steer- Stable on off-camber sidehills (an easy thing to forget when going for flex)- Lower control arms mounted above the bottom of the frame rail- ZERO bind, including spring mounting points

As always, this will likely be a battle of compromises, involving a little study in the field of suspension design theory. Believe it or not, where you locate your links involves more than just clearance and articulation issues, especially on a vehicle that will be street-driven. And located incorrectly, the torque of the motor can actually create a lifting force (moment) on the axle! …Not exactly the hot ticket for traction in the rocks…

Coils in front and 1/4 elliptics in the rear seem to work quite well, although there are a lot of differing opinions on rates and so forth. I have my own opinions based on research, but in the end, I think this is something you’ve just gotta refine by trial-and-error.

Some have elected to use nosebleed-expensive ($400+ EACH!), extra-long, coil-over shocks of the type used in Baja trucks. However, I have serious reservations about the valving rates in these little jewels, for both on-road and rock-crawling usage. Not to mention the ticket price!

Approach/Departure/Breakover Angles: 80 approach, 90 departure, and the absolute best breakover possible.

By “clocking” or raising the output side of the tcase 15 degrees, I can make a completely flat skidplate that rests directly against the bottom of the frame rails. Cutting out the front crossmember tube and moving the winch behind the front of the frame will do wonders for approach, and hacking off the entire rear cargo area will get me my departure angle.

Weight: Maximum of 2000lb., ready to rock, with a 60/40 front/rear split.

Mazuki had porked out to over 2300lb., and carrying the winch, Optimas, jack, etc up front probably put me in the 75/25 neighborhood. A lot of folks will tell you nose-heavy will allow you to climb better, by virtue of keeping the front tires on the ground longer. While true to a point, this small advantage does not outweigh the disadvantage of an overly-heavy nose wanting to wash to one side or the other in a hard, steep climb, especially on a loose surface. A heavy nose will come around (or, “wash out”) much faster when the going gets vertical and off-camber.

Center of Gravity (CG): Measured as static sideways tip-over angle, I want 10 degrees more than I’ve got now. I’m after 5 degrees more climb angle, and 15 degrees more descent angle.

By moving everything heavy as low as possible, and making those high things I can’t move as light as possible, I should be able to reach these numbers. For instance, moving the 35lb. Optima battery from it’s stock location to the floor behind the passenger seat will make a difference. Using .090 wall DOM tubing in the roll cage, versus .120 will still do the job, but is substantially lighter. (.090 DOM is what the local circle-track race cars and 8,000lb. monster trucks are built with, so I’m pretty comfortable with it on a low-speed lightweight crawler.)

My current setup consists of rear Zook springs up front, and CJ main leafs in the rear, with the 1/2″ lift Missing Link shackles on both ends and zero-lift SPOA pads. I plan to set my ride height 1″ to 1-1/2″ LOWER than I am at right now, mostly due to the coil spring height I want to use in front. This will cause more than a little interference with the bodywork due to much greater axle articulation, but since I planned on hacking the fenders as necessary to accommodate stuffing my 33×12.50 MT/Rs, it’s no big deal.

I’d rather lose some sheetmetal than raise my CG any day.

BTW, lifting your vehicle to clear bigger meats (tires) is the absolute WORST thing you can do to your CG. Now you’ve raised your CG by basically the amount of your lift, and in the case of the Samurai, set it on top of soft, boingy springs. Remember those cast iron playground toys in the shape of an animal, attached to the ground with one spring?

Body lifts aren’t a whole lot better, and like excessive spring lifts, are basically treating the symptom.

Steering: Full-hydraulic is where it’s at. One-finger turning in the rocks is bliss.

The trick here is not only getting the ratios right for on-road travel, but using the correct valve body that will allow steerage with loss of the pump, and making triple-sure that the hoses are top quality and protected from any imaginable damage. This is an extreme compromise on my part, one that I may go back on later. If I do back off to power steering, the system will be off something like a full-size GM truck, not a donut-tired Sidekick!

(Note: I have talked to two folks who’ve used the new “power-assist” steering rams, and they both said it really didn’t perform any better than regular ‘ole power steering.)

Also, I plan on the possibility of fitting four wheel steering in the future, so the frame structure I build in the rear must provide clearance for the tires to turn while the axle is articulated.

Roll Protection: Both passengers and bodywork.

There are two types of rock crawlers; those that have rolled and those that will. *When* the day comes, I want Mazuki to come out unscathed, like a Sand Rail, instead of looking like a refugee from war-torn Bosnia. The cage will be designed so that the top is semi-curved, preventing her from coming to rest completely upside down. It will also allow easier ingress/egress, while providing better noggin protection.

Styling: Unique. (period)

Being a Designer, I want to give the vehicle an extremely unique look, a look I’m coining: “Skin And Bones”. Retaining just enough of the Samurai sheetmetal to provide a family semblance and weather protection, while insuring plenty of clearance for all the hard parts. The remainder of the “bodywork” will consist of box- and round-section tubing, brushed aluminum panels, and a few “surprises”.

And last, but not least, Budget: Keep it simple, and cost-effective.

Next month is “Fun With Mock-ups”…

08/11/10 14:52